Labels

Labels are just small signs, so the processes that we use to create premium quality signs will also make particularly fine quality labels. Mass production of standard labels is not something that we do, but there are many applications where the superior quality of our processes, and our attention to detail, will deliver what your customer requires.

For when quality counts

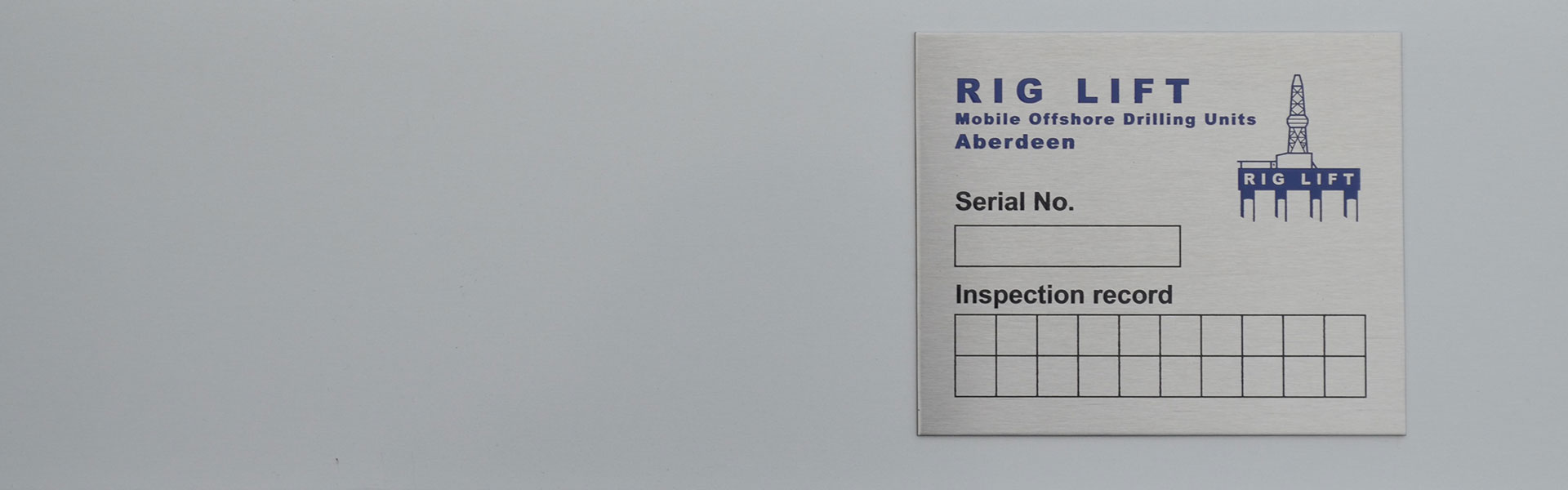

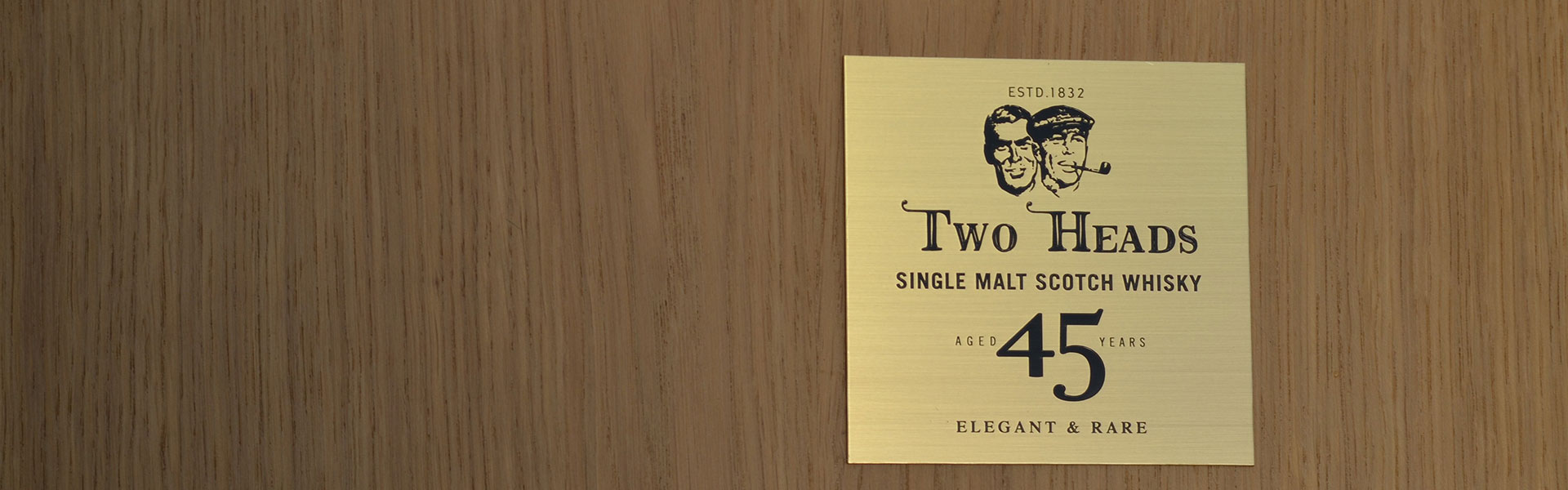

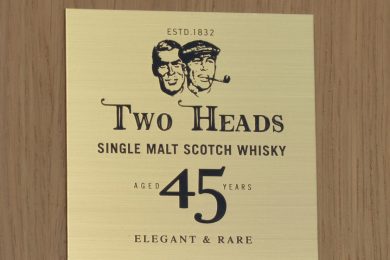

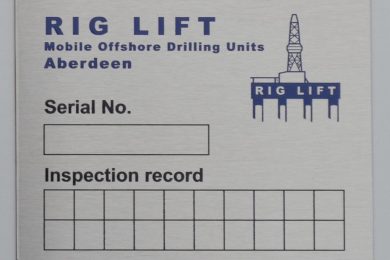

Typical label projects that suit our way of working rather than the mass-producers are small runs, particularly one-off plates, labels that have to meet a particular specification to endure high temperatures or extreme environments, labels which all have unique details such as serial numbers or location references, and labels that require a high-quality appearance such as for product branding or point of sale display.

We only use the highest quality materials for all of our products, so no matter what grade of material your customer requires, we will meet or exceed their quality requirements. Except for particularly unusual projects, we always use 316 marine grade stainless steel for example. All of our aluminium is anodised to a minimum of 25 microns, so will withstand extreme weather, marine and offshore environments.

Most importantly of all, we have decades of experience of supplying products for a huge range of environments, from arctic pipelines to deserts, from saunas to swimming pools. We understand catering environments, and the unique challenges that can be found in pharmaceutical plants. We are familiar with the industrial needs of offshore labels, but we also understand how to take extra care to make plates beautiful as well as functional. We believe that we have a unique range of skills for this market, and combined with the exquisite graphic quality of our manufacturing processes, we are confident that we can exceed all of your customer’s expectations.